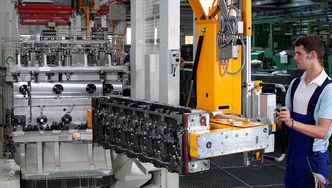

HELLER solutions at MAN

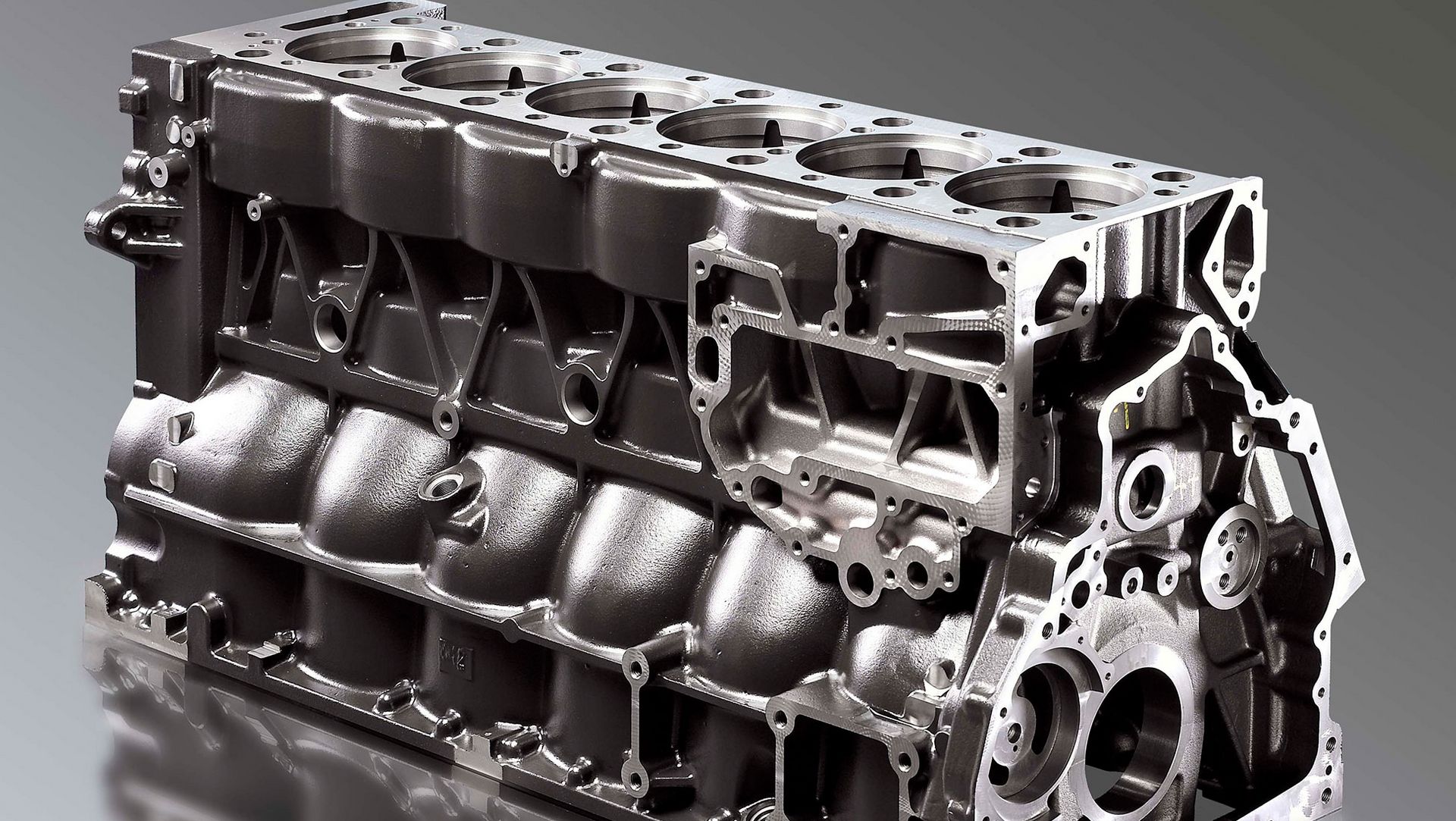

Successful product and process development of an ultra-modern 6-cylinder diesel engine

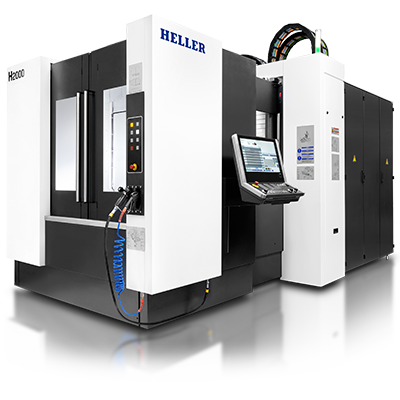

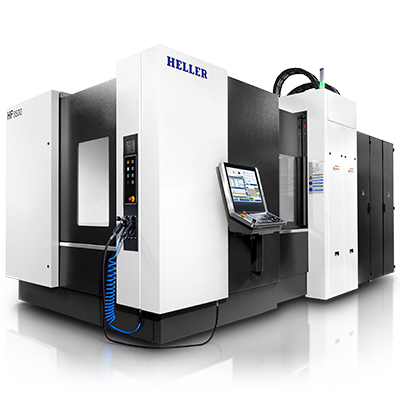

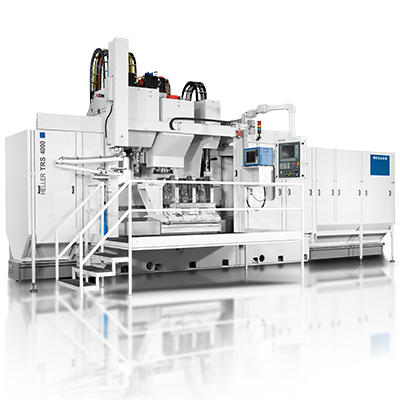

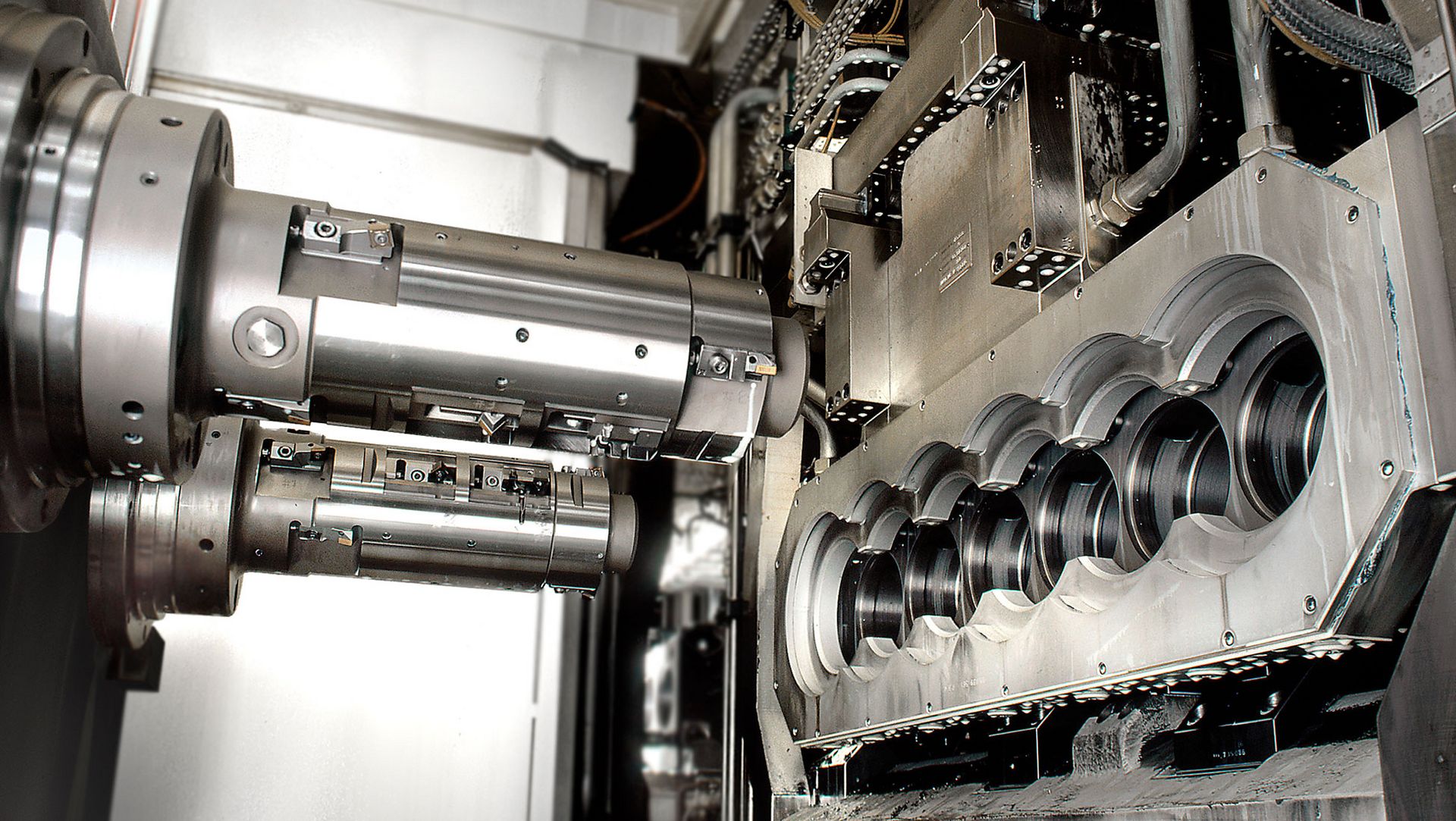

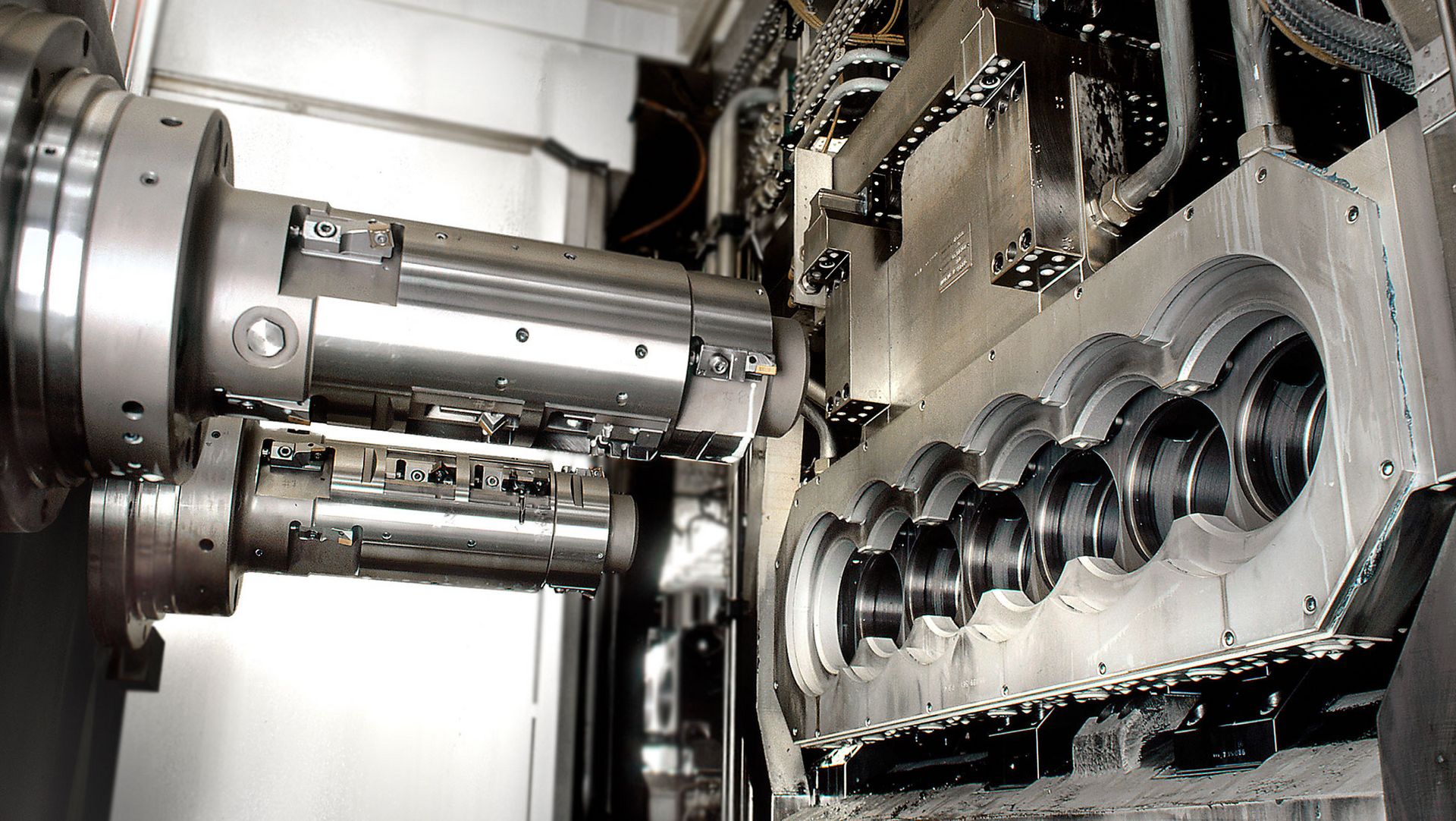

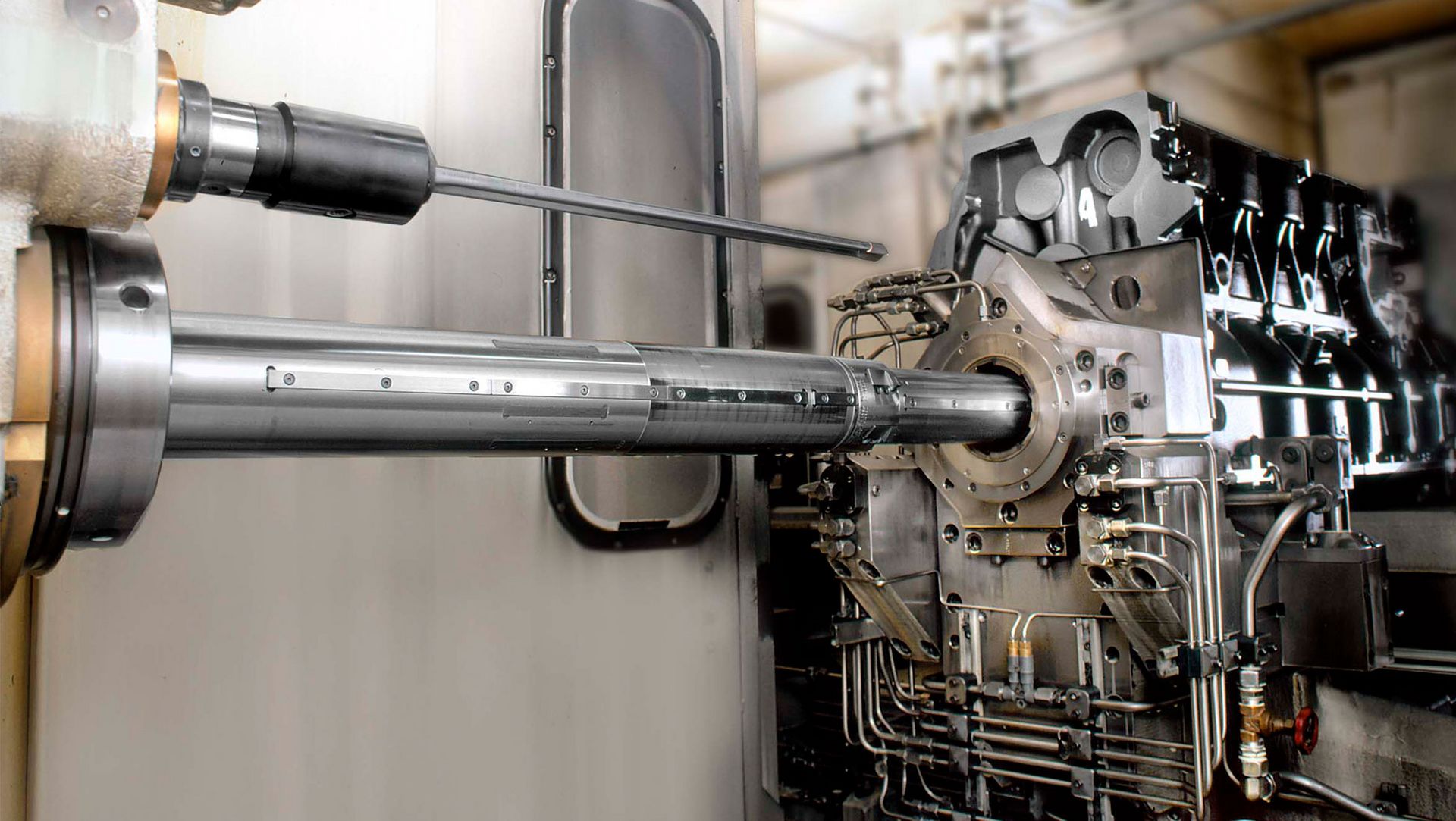

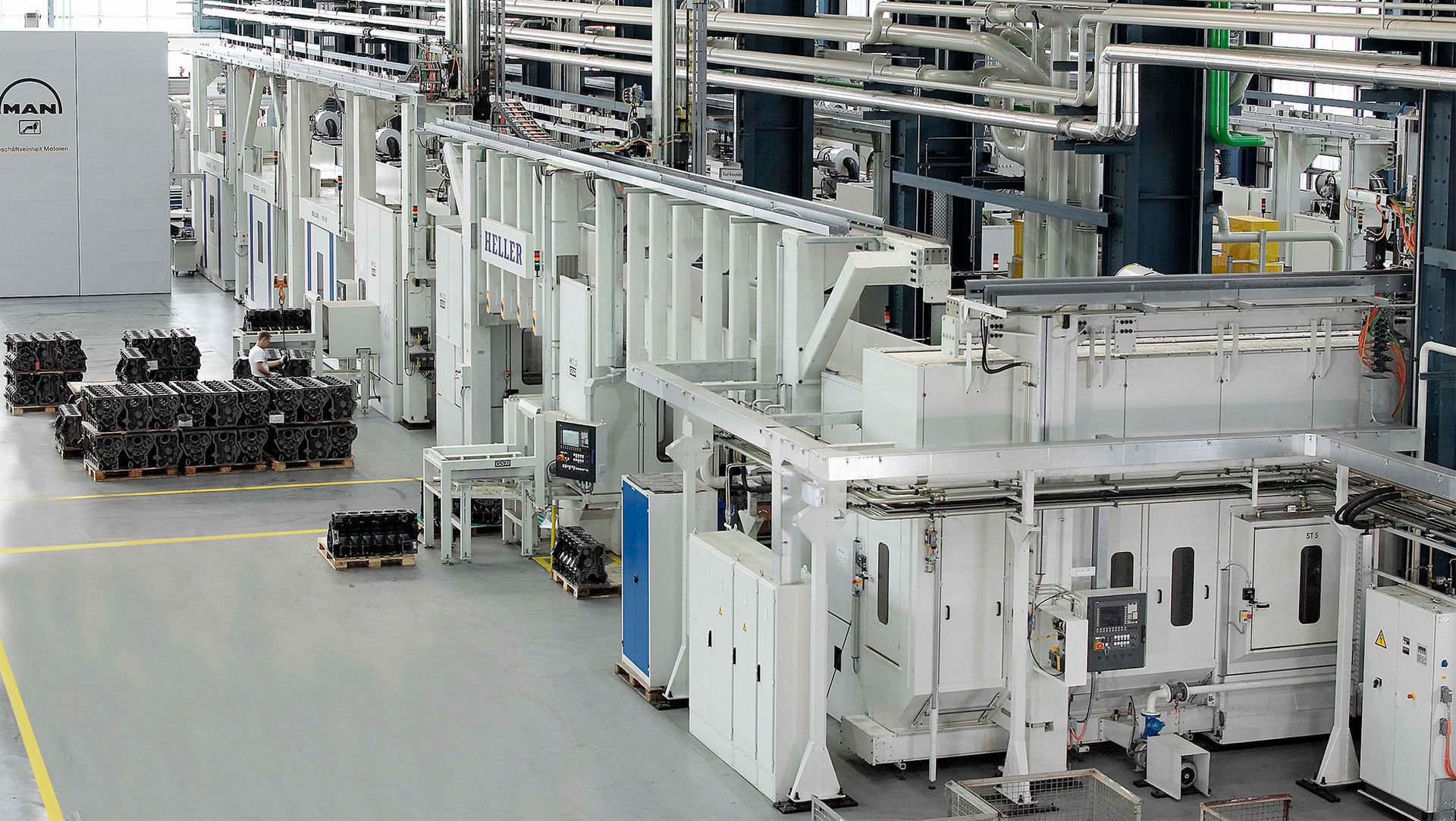

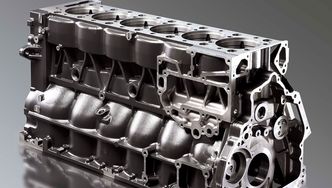

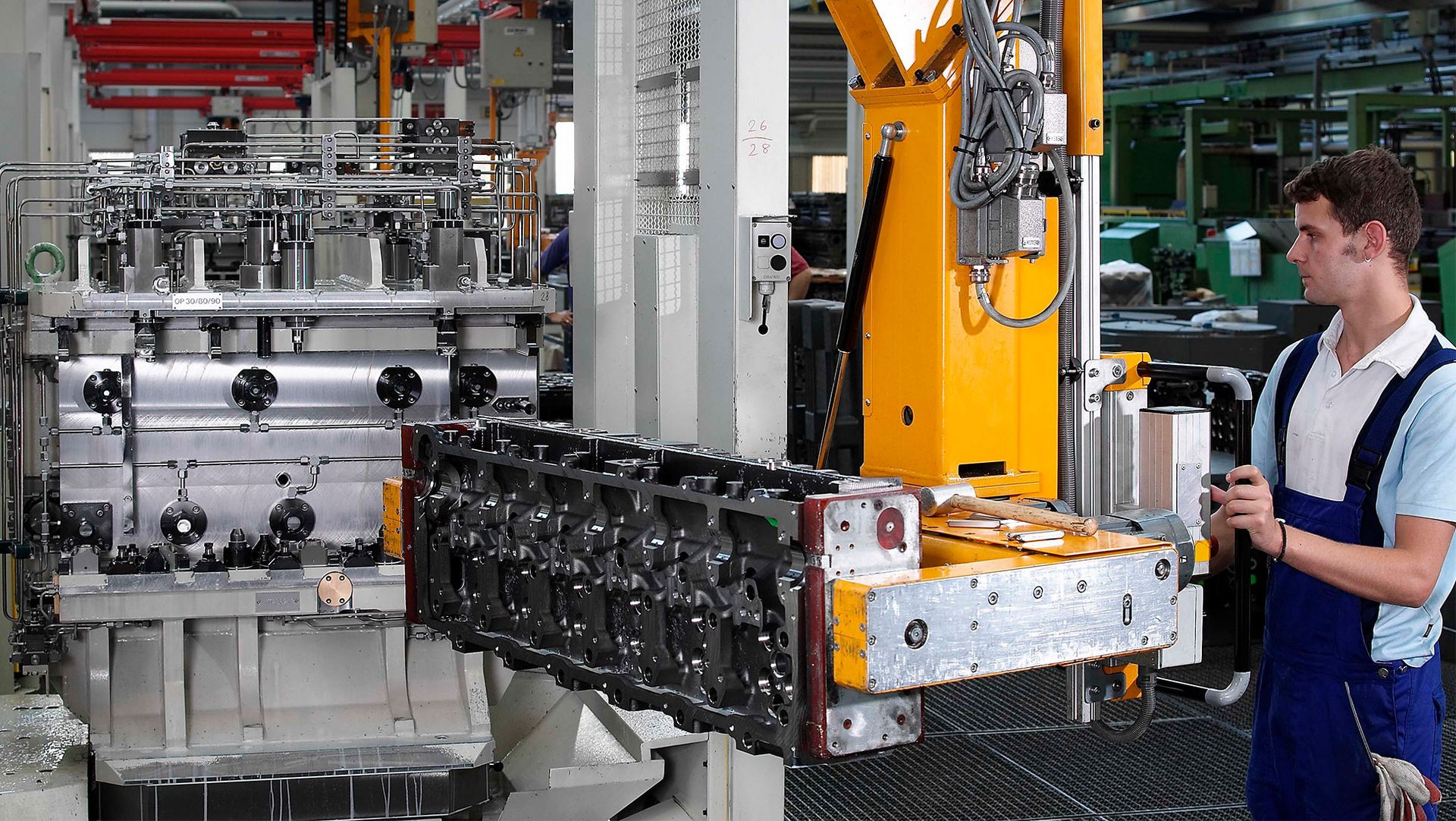

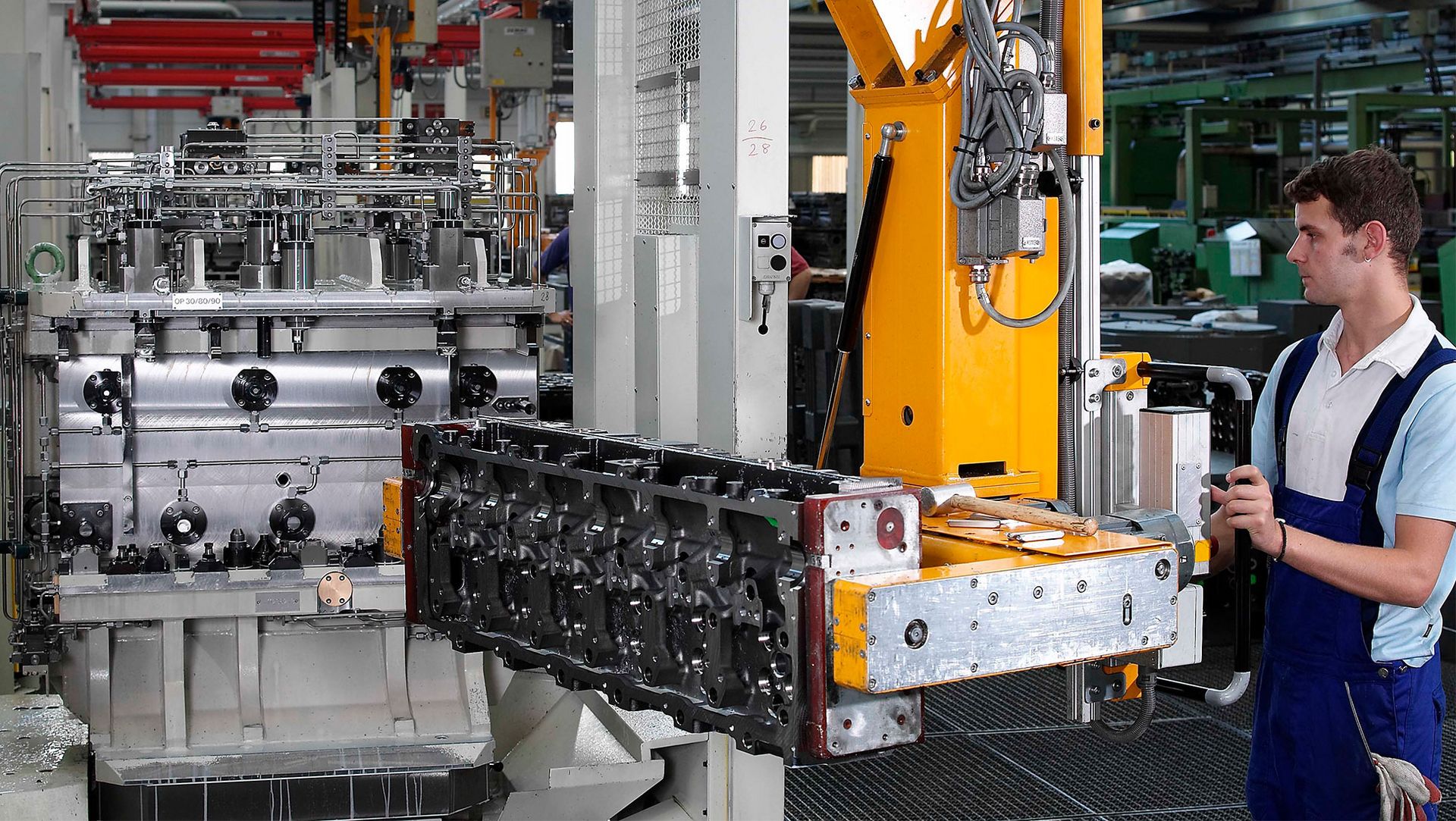

The manufacturing task concerned 6-cylinder diesel engines with common-rail technology. HELLER contributed the entire know-how for the required modifications resulting from ongoing product and process development. The result are four transfer systems comprising four to six machining stations and 18 MCH 400 machining centers.

Task

- production of a 6-cylinder diesel engine with common rail technology

- product and process development (simultaneous engineering)

- high flexibility and comprehensive engineering know-how

Project scope & solution

- four "FST" transfer systems, each with four to six machining stations and 18 MCH 400 machining centers

- material transport with "lift-and-carry" system or linear loader

- in-process gauging for comprehensive quality assurance

Result

- 25% fewer components

- weight saving of 100 kg per engine

- compliance with all existing and future emission standards

- extension of maintenance intervals to 120,000 km

- 5% less fuel consumption

Contact

Contact

Sales & Services

Do you have questions about our products and services? Please get in touch with us, we are here for you! Benefit from our global HELLER network with knowledgeable sales and service contacts located in your region.

Find your nearest personal contact.

No results could be found.

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!