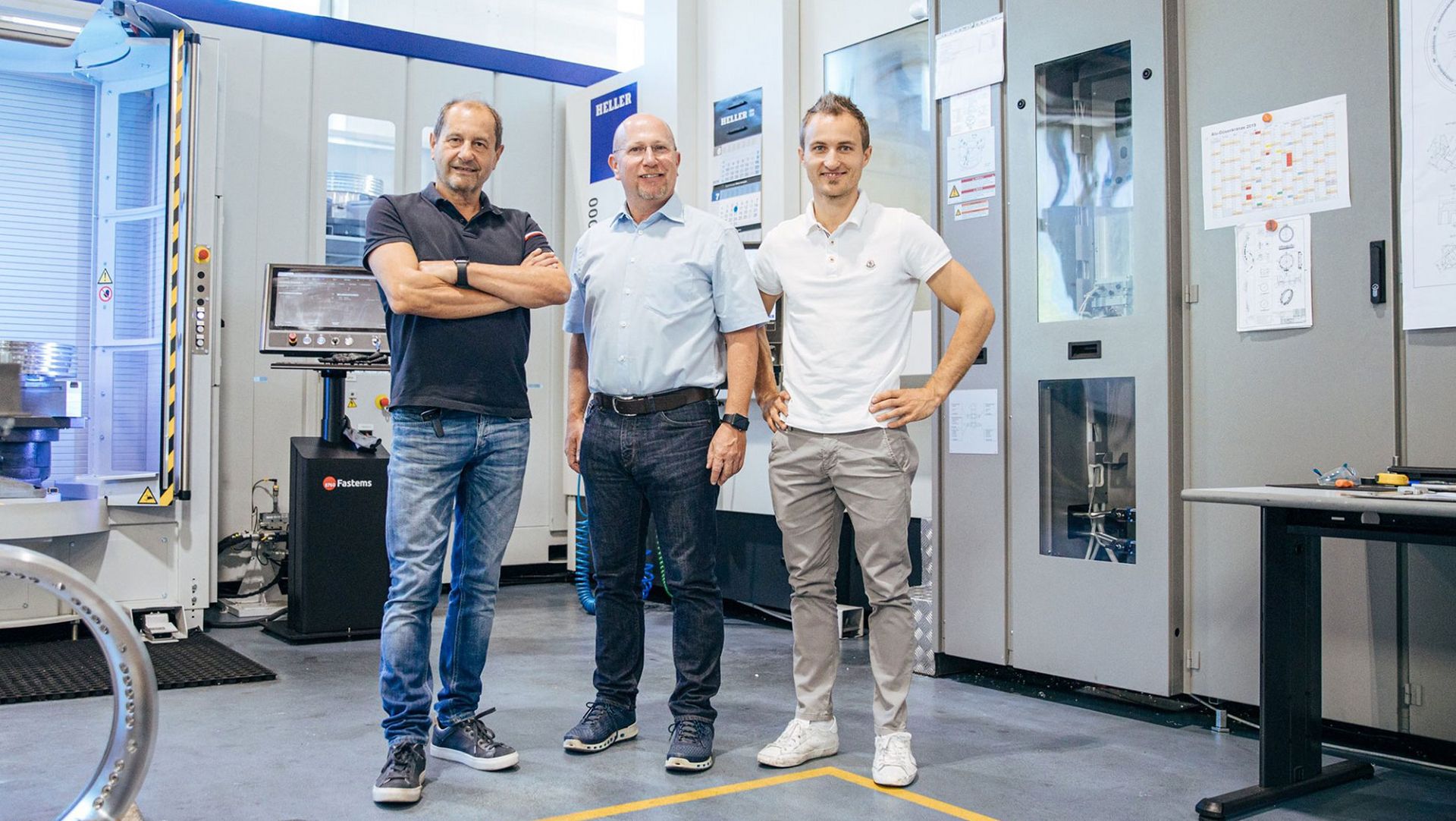

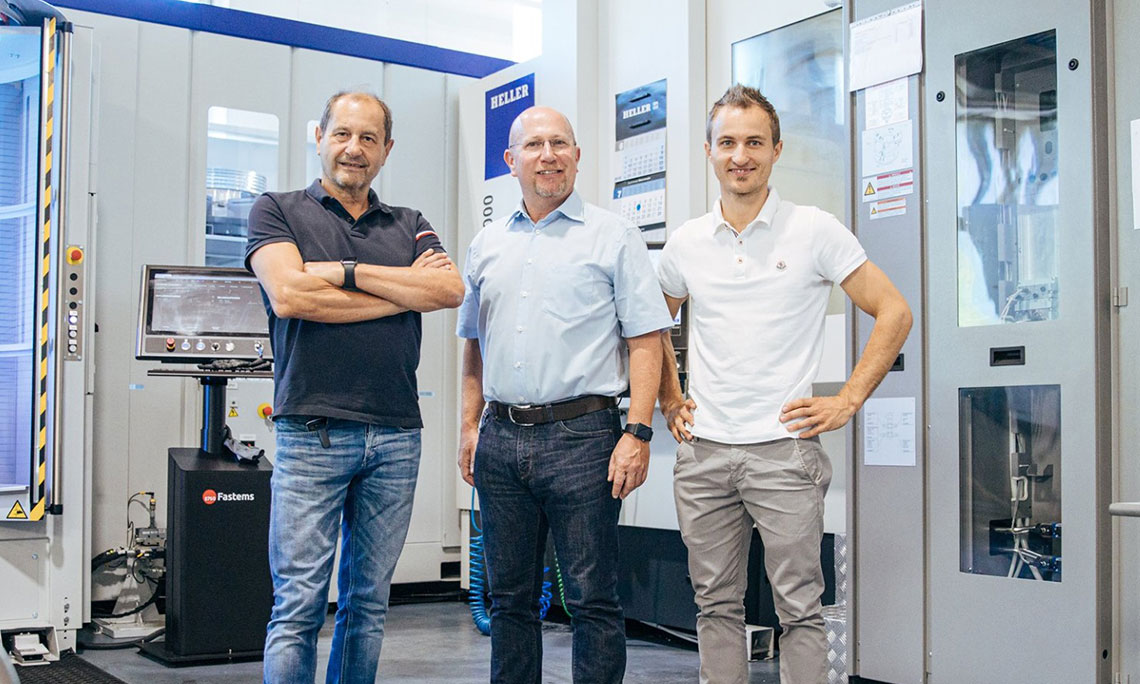

HELLER solutions at WF Mechanik

Increasing productivity and reducing downtimes

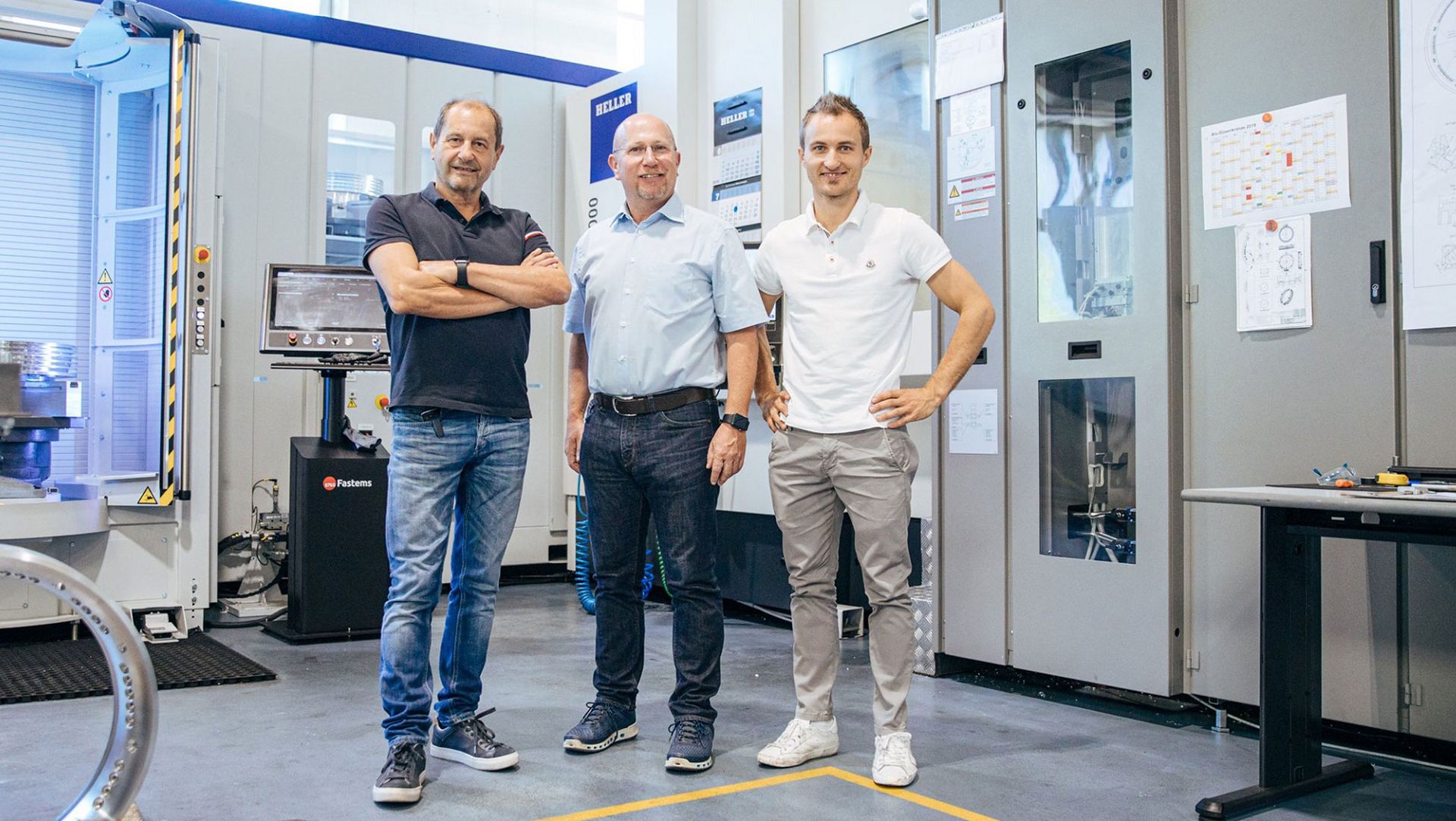

The company has been processing high-quality metals since 1979 and soon needed a new production facility in Varna, where it currently has around 50 employees. The early automation and the use of digitally controlled machines, robots and fiber lasers make WF Mechanik a market leader in the processing of high-quality metals and the manufacture of finished and semi-finished parts for the mechanical engineering, electrical, tool and automotive industries – not least by commitment to Industry 4.0 and the use of non-metallic materials as well

as innovative 3D technologies.

Task

- reduce the existing production time

- establish a stable manufacturing system that produces the parts in time, with high quality and without any faults – 24h per day

Project scope & solution

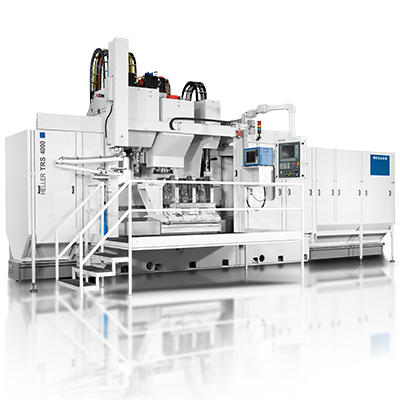

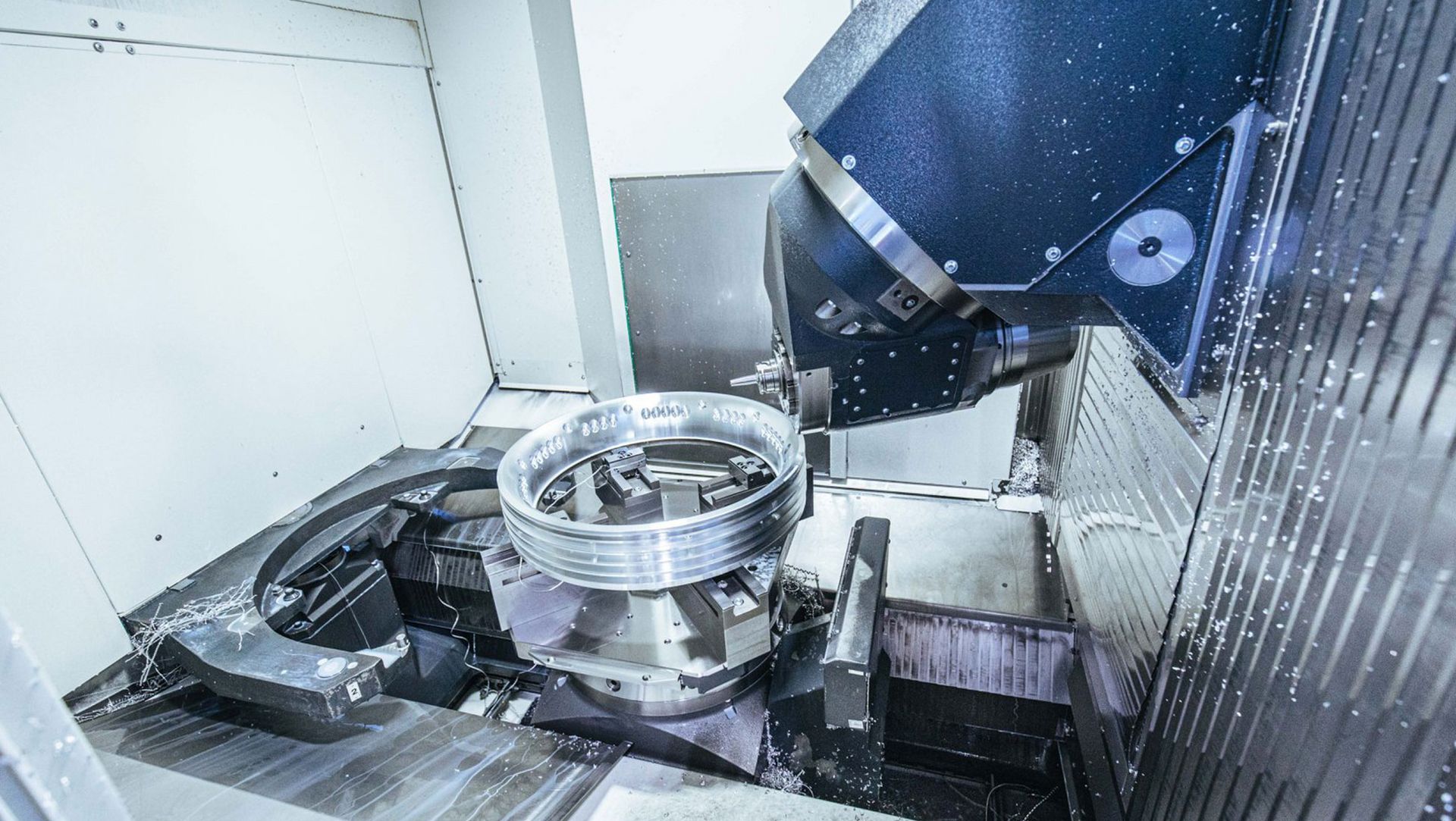

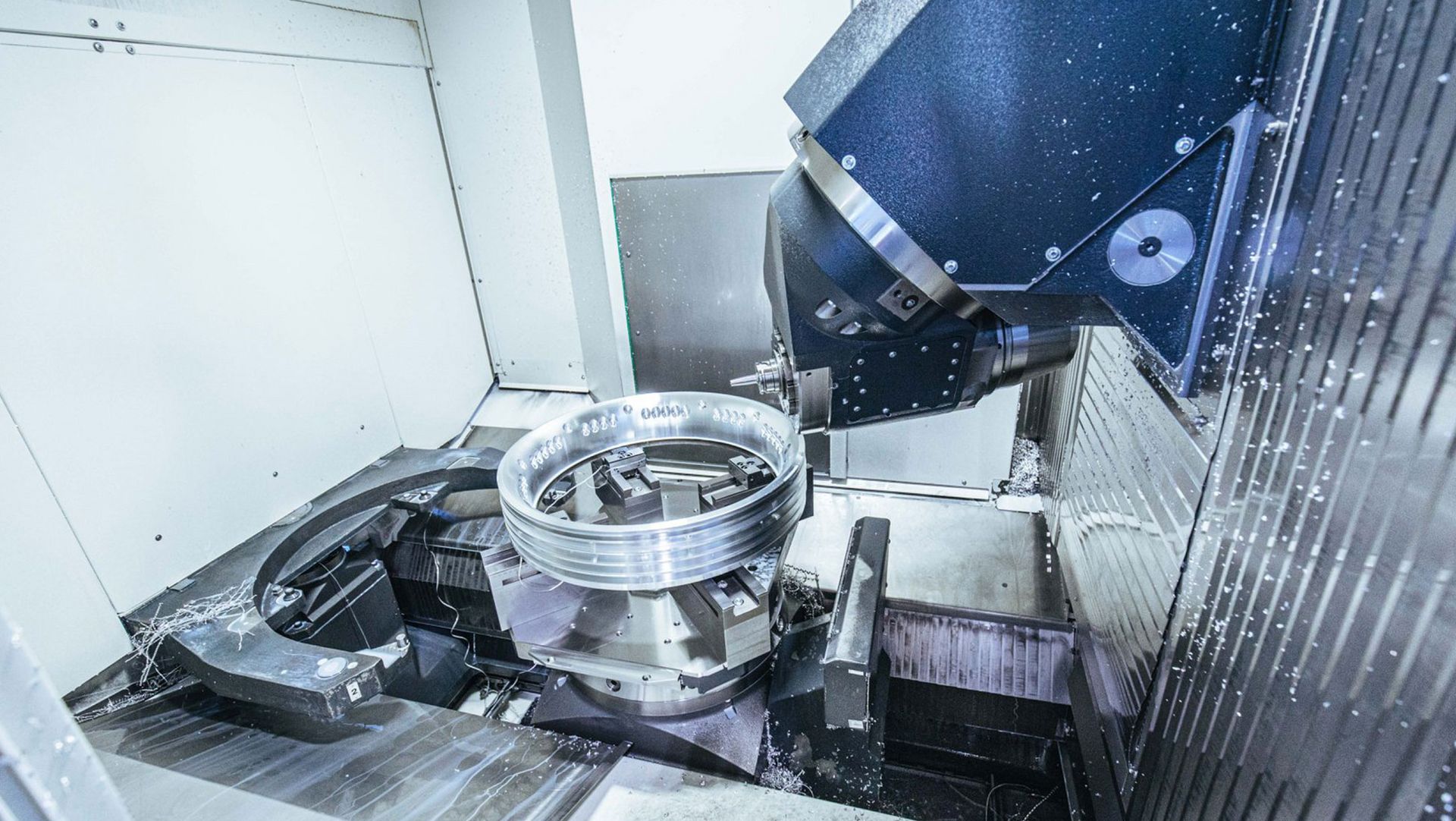

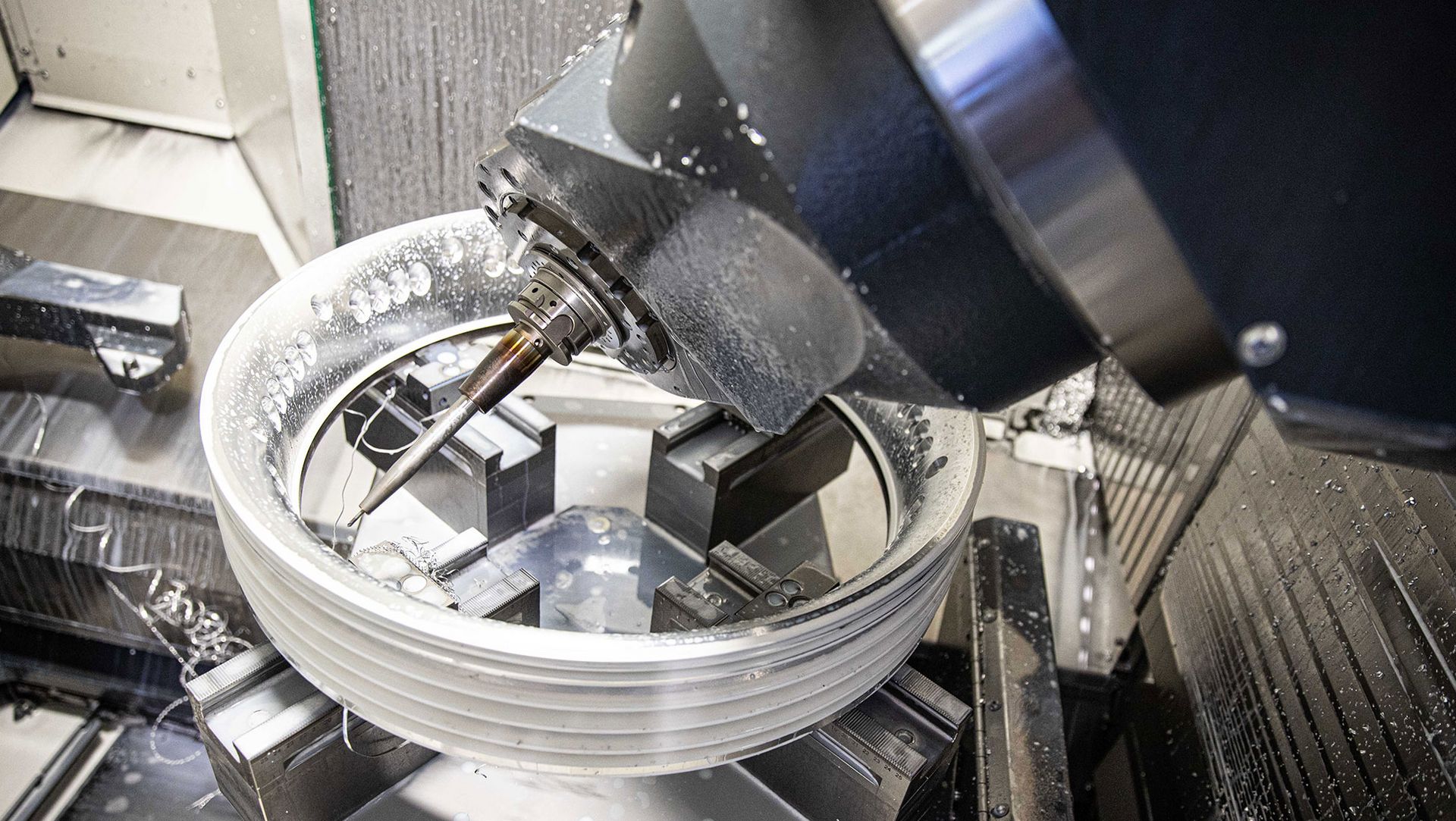

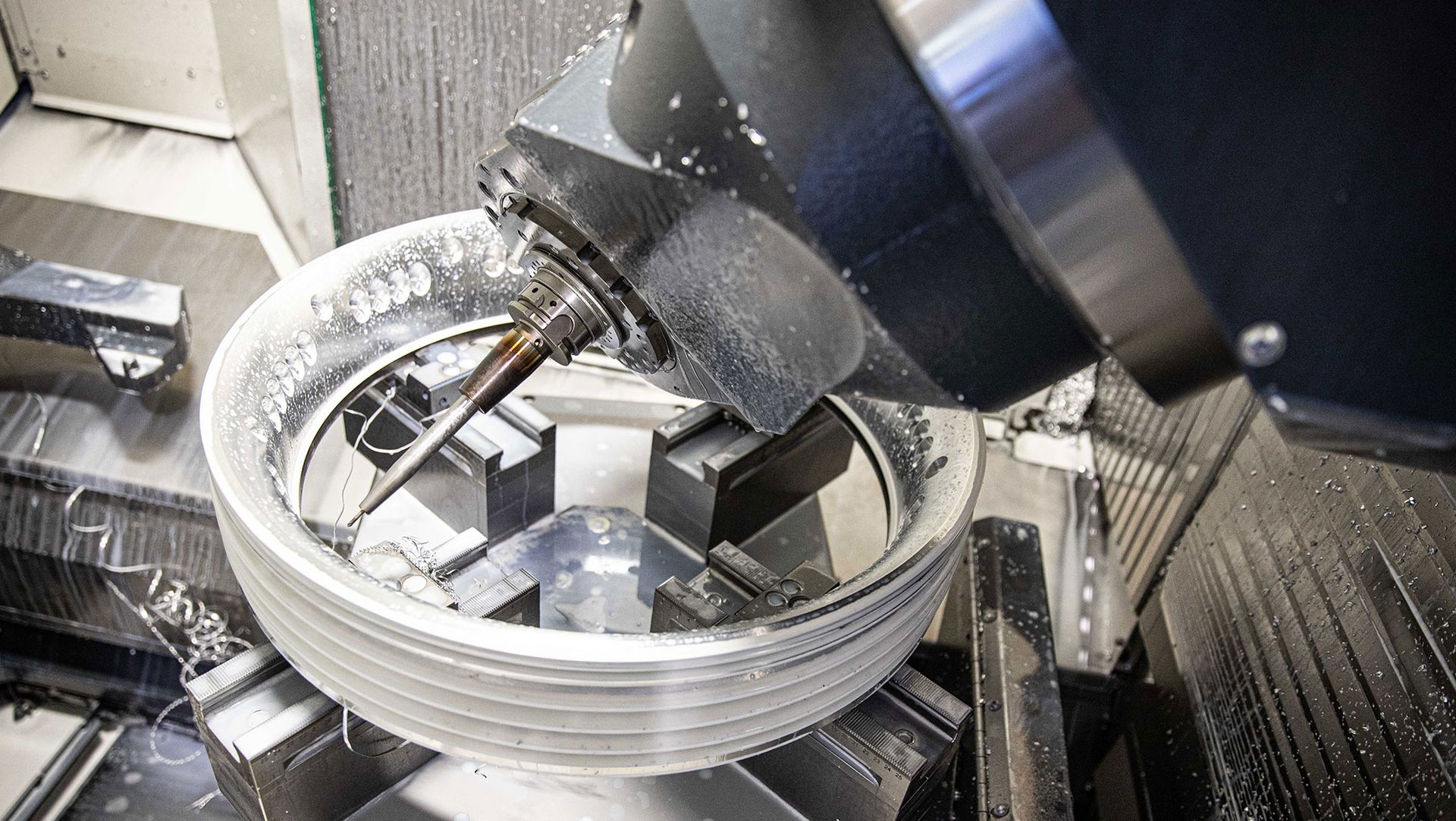

- 5-axis milling/turning machining center CP 4000 with Fastems system for combined mill-turning processes. The CP 4000 performs approx. 70% milling and 30% turning operations.

Result

- full automated project with the 5-axis milling/turning machining center CP 4000 and Fastems automation system for in total 12 pallets

- 24h/6 day production of water distributions for snowing cannons and other relevant parts for snowing cannons

Contact

Contact

Sales & Services

Do you have questions about our products and services? Please get in touch with us, we are here for you! Benefit from our global HELLER network with knowledgeable sales and service contacts located in your region.

Find your nearest personal contact.

No results could be found.

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!