HELLER solutions at Engel Austria

Capacity doubled & drastically reduced idle times, thanks to HELLER

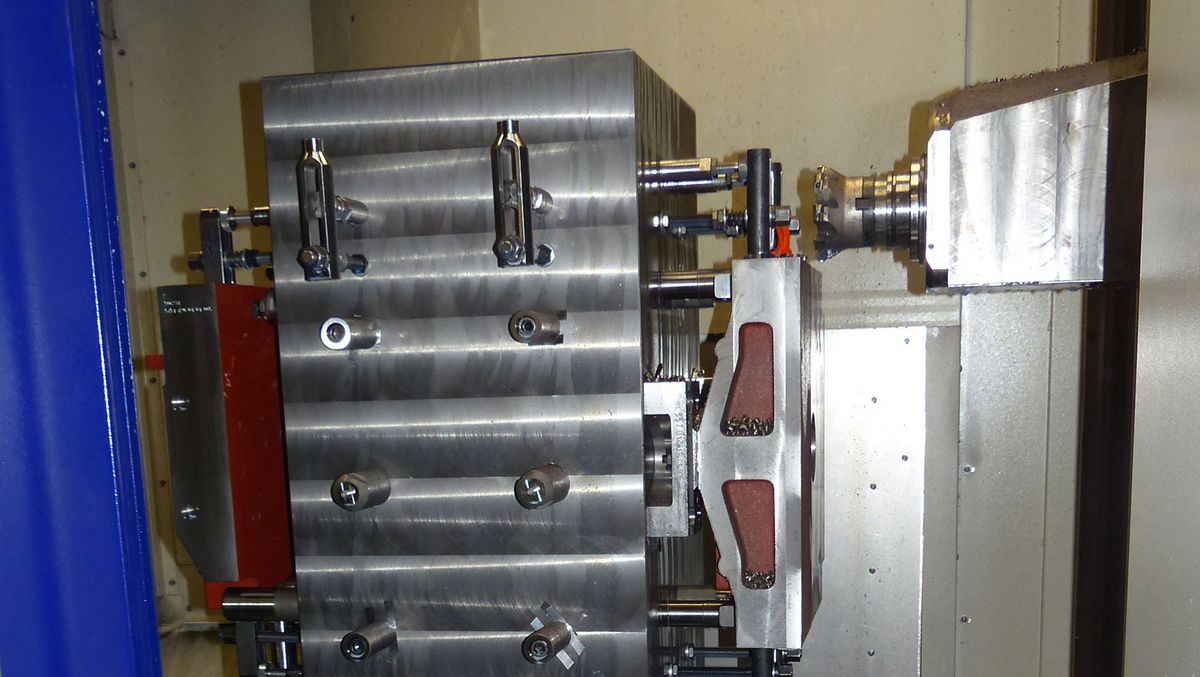

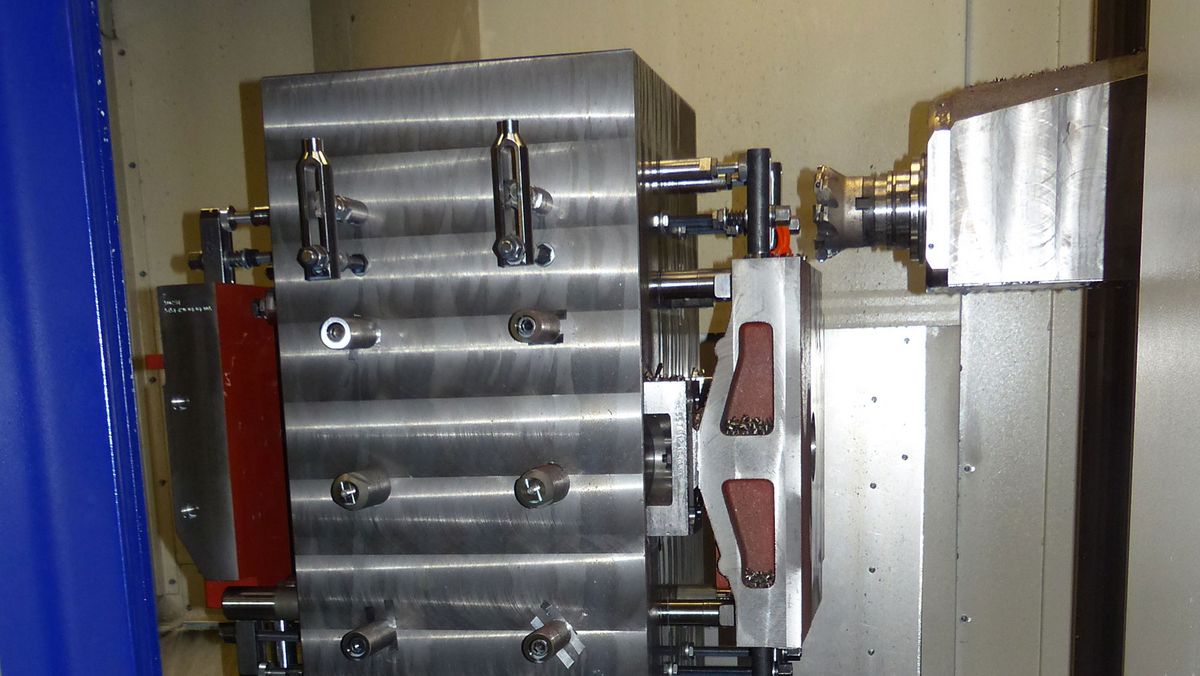

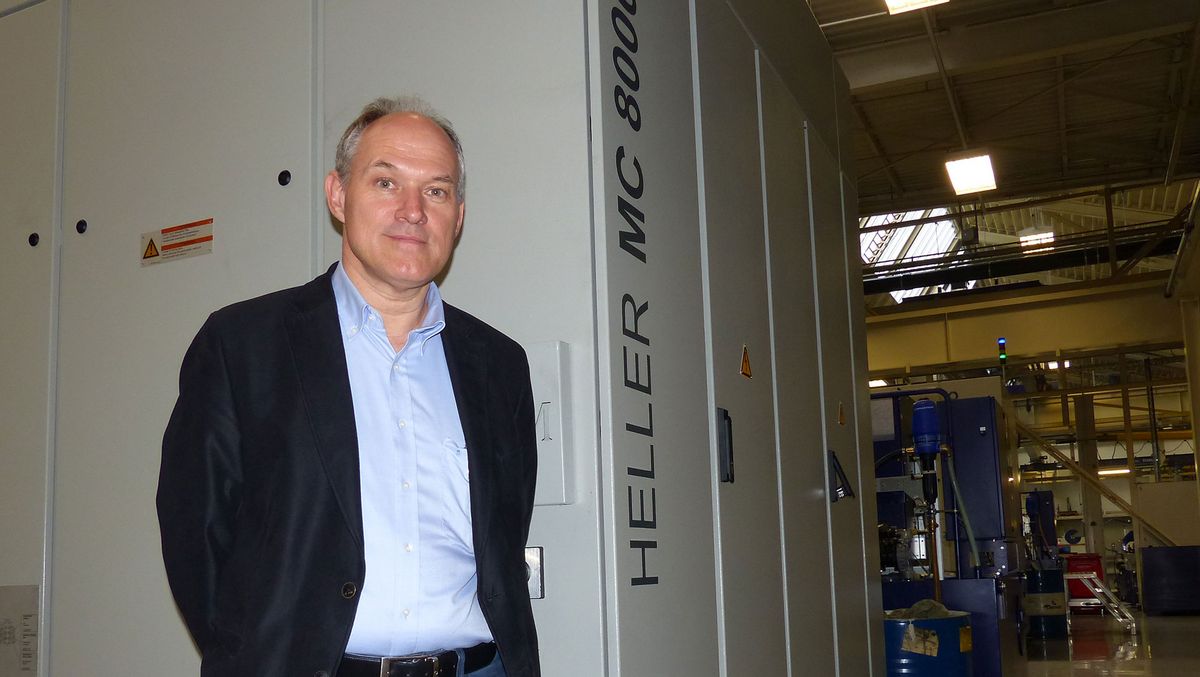

State-of-the-art and highest performance manufacturing line at Engel Austria in Schwertberg: Three HELLER H 8000 4-axis machining centers are primed to gradually double capacity and reduce idle times by up to 20 percent in an automated network. Even in the run-up phase, these targets are within reach.

Task

- to cut manufacturing costs of the core components for injection molding machines by 17 to 20 percent through shorter machining times

- to relocate 500 different components from stand-alone machines to an interlinked manufacturing line

- to double capacities and optimize setting processes to reduce the level of outsourcing

- to comply with the just-in-time delivery promise, even in case of fluctuating order levels

- tolerances for core components are between two and three hundredths of a millimeter

Project scope & solution

- three HELLER H 8000 4-axis machining centers in service: one machine for cast iron, one for steel and one for the cast iron/steel combination

- two of these machining centers are equipped with the HELLER facing slide solution

- Fastems automation system with 156 pallets

Result

- improved capacities and shorter idle times

- increased system availability

- high component quality guaranteed

Contact

Contact

Sales & Services

Do you have questions about our products and services? Please get in touch with us, we are here for you! Benefit from our global HELLER network with knowledgeable sales and service contacts located in your region.

Find your nearest personal contact.

No results could be found.

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!