HELLER solutions at Georges Pernoud

Individual manufacture of cast workpieces economically and precisely automated

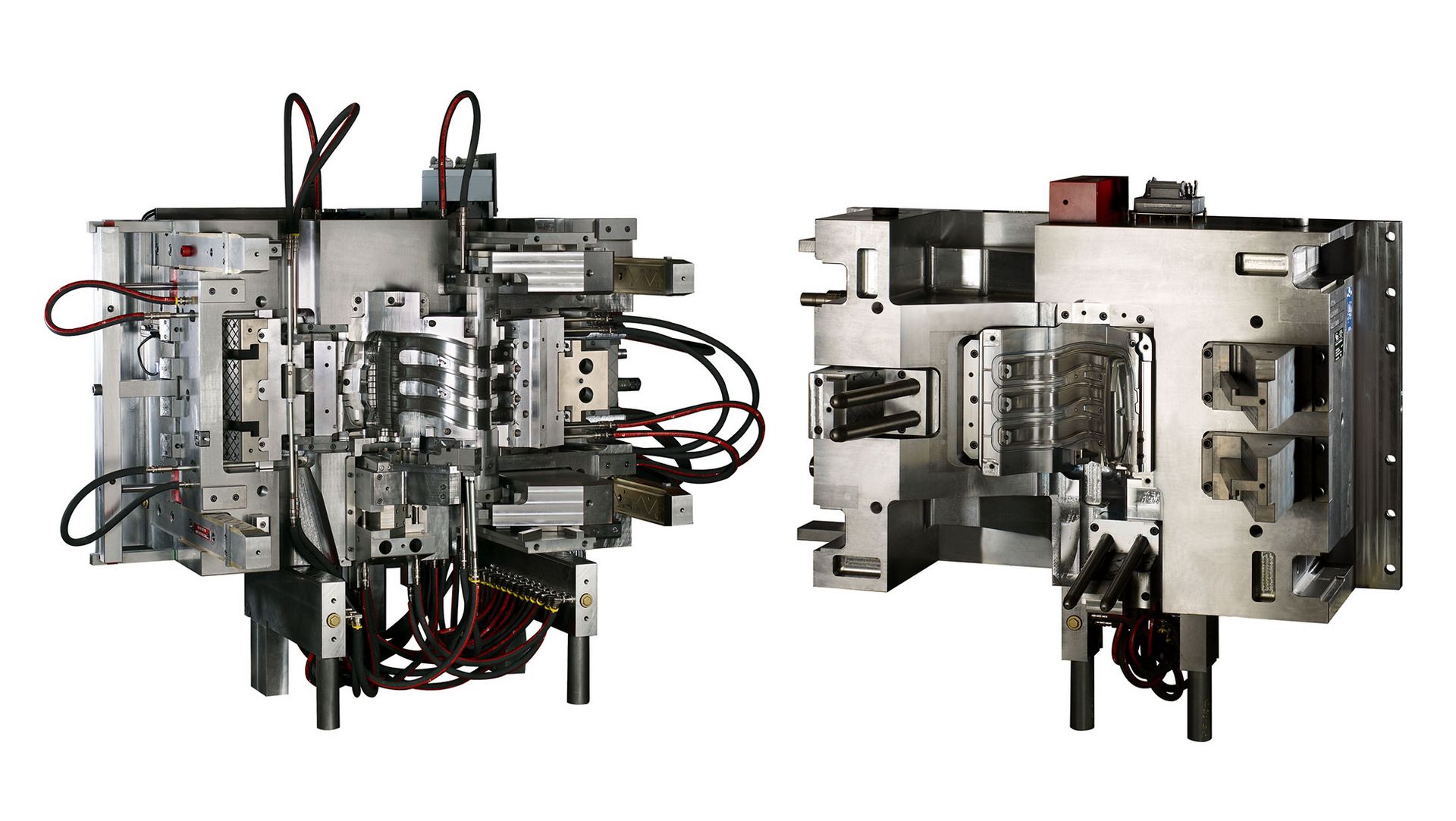

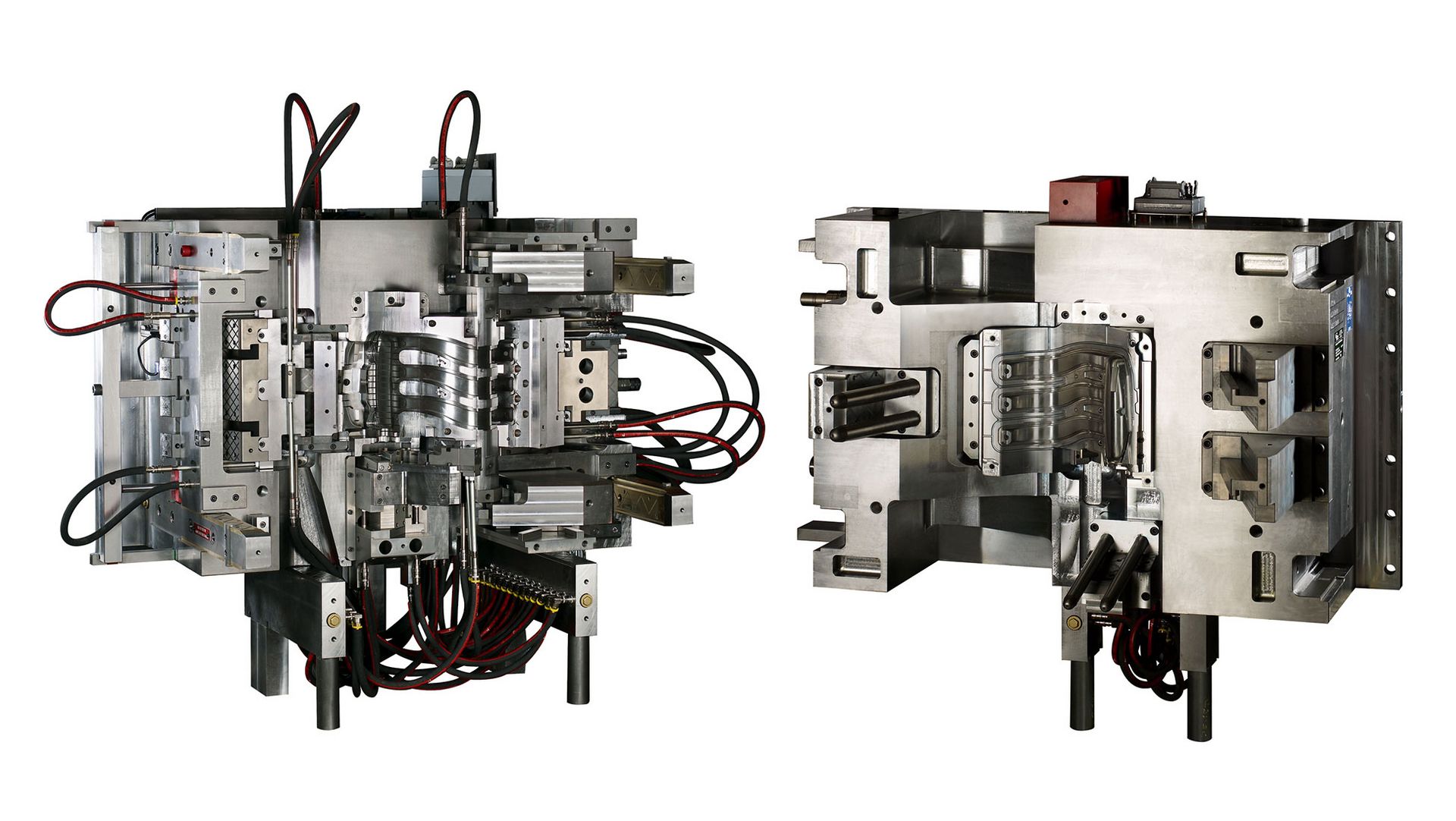

The French mould and die manufacturer Georges Pernoud SA based in Oyonnax uses industrial machining processes to produce individual parts and therefore opted for the HELLER 5-axis machining center model MCH 350-C. By now, the company has made a name for itself in the industry with high precision and extremely short delivery times.

Task

- fast and economic production of single workpieces

- high machine running times for optimized productivity

- high machine availability

- high degree of automation

- complete machining in 5 axes

- horizontal machining of pockets with a high chip volume

Project scope & solution

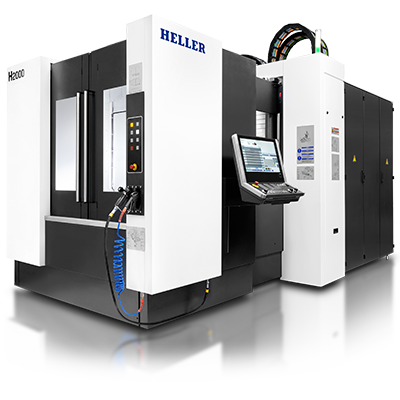

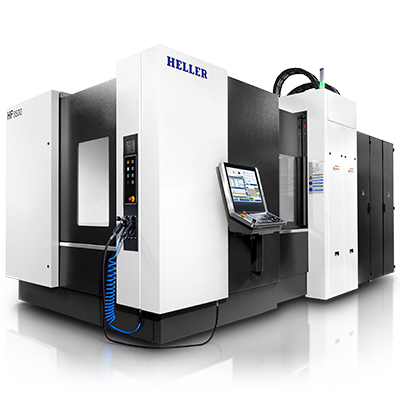

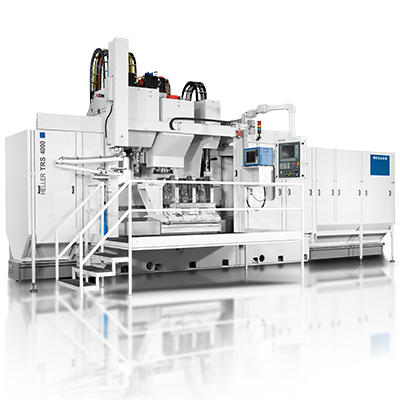

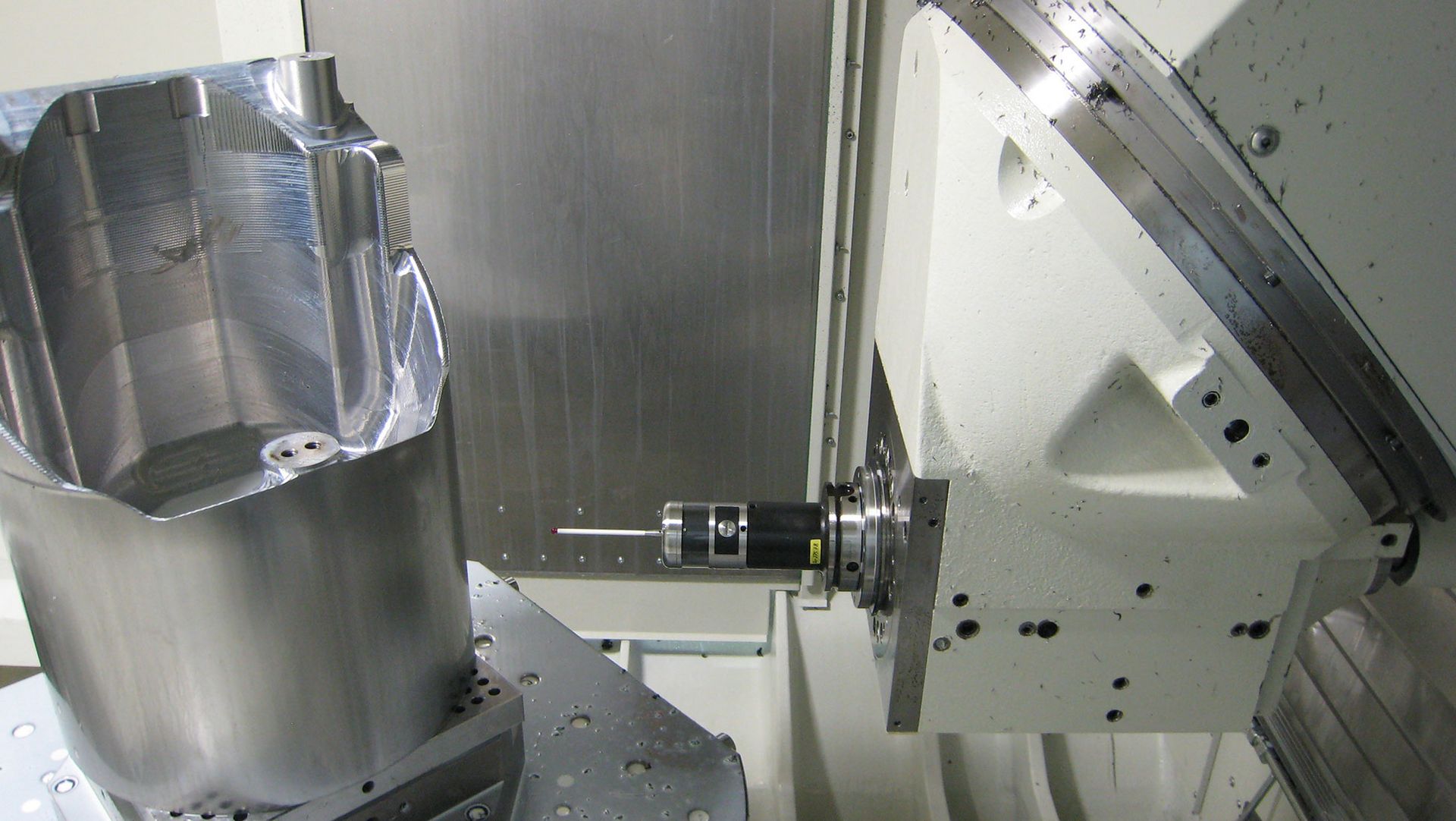

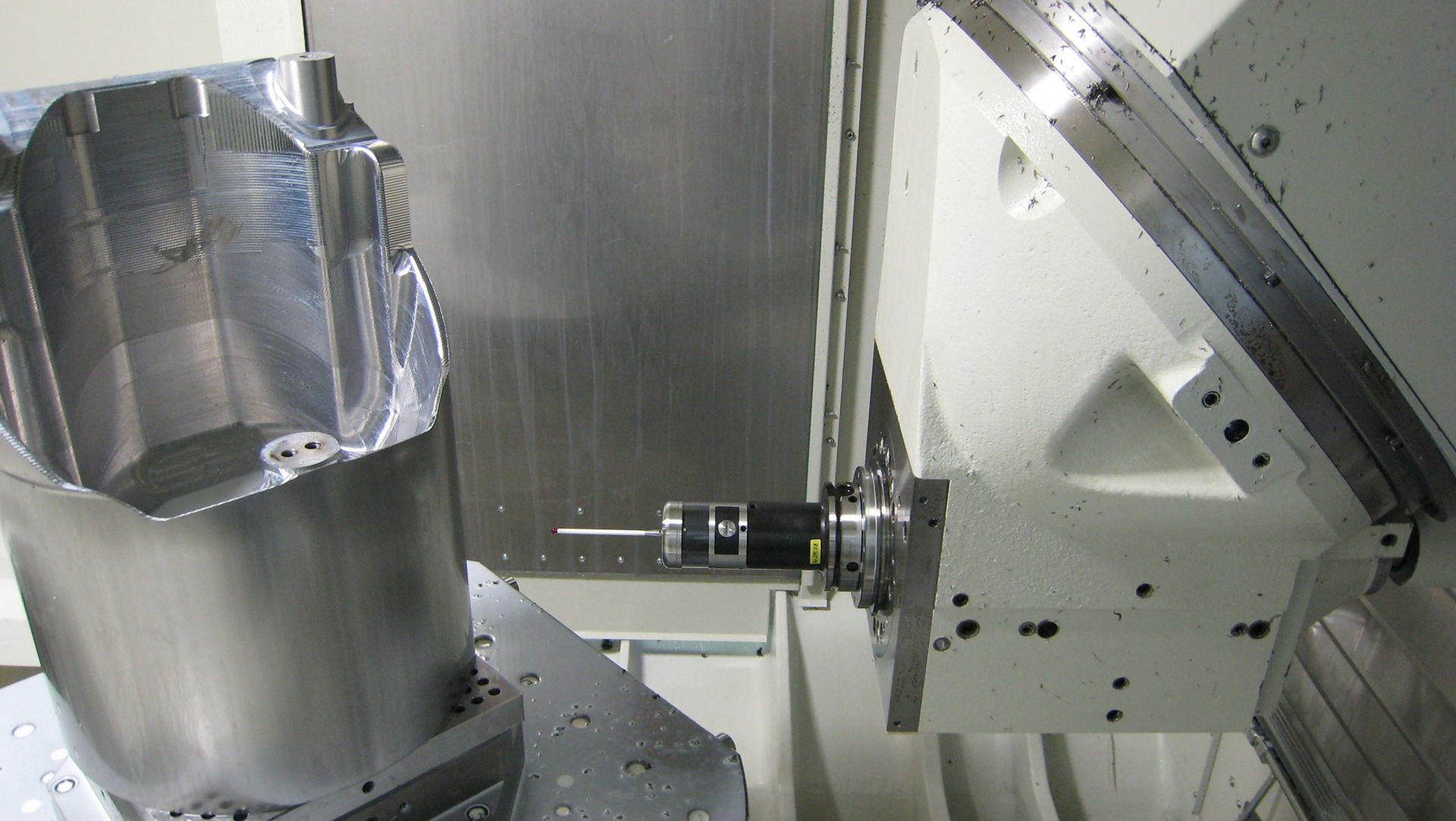

- HELLER MCH 350-C 5-axis machining center

- machine configured for optimized processes, individually adapted to the requirements in injection molding and die casting

- tool magazine for 234 tools with tool cleaning device

- laser control module for wear and tool break monitoring

- rotary pallet magazine with six pockets

- 3D check of workpiece conformity with gripper arm for high precision

Result

- 24-hour production of complex single workpieces and mold frames

- economic and precise automated production

- increased competitiveness with new machining options: full machining of complex die casting molds, as well as large and complex single workpieces

- high precision and extremely short delivery times

Contact

Contact

Sales & Services

Do you have questions about our products and services? Please get in touch with us, we are here for you! Benefit from our global HELLER network with knowledgeable sales and service contacts located in your region.

Find your nearest personal contact.

No results could be found.

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!