HELLER solutions at Komax

Up to 20% faster production rates

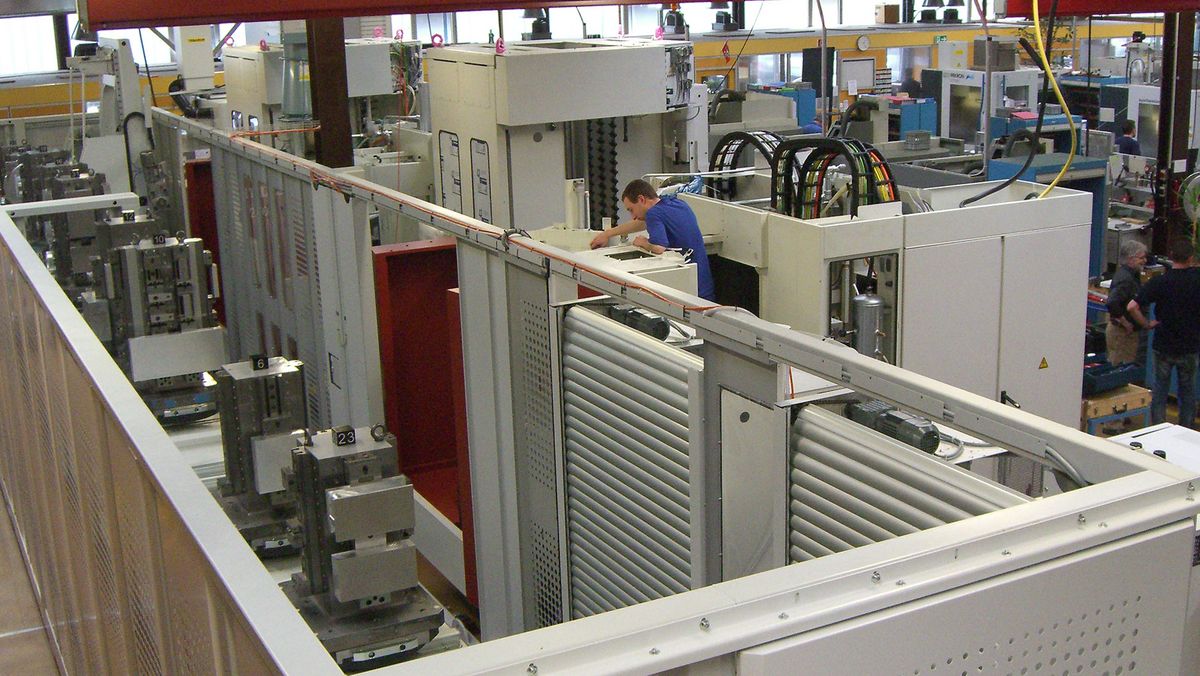

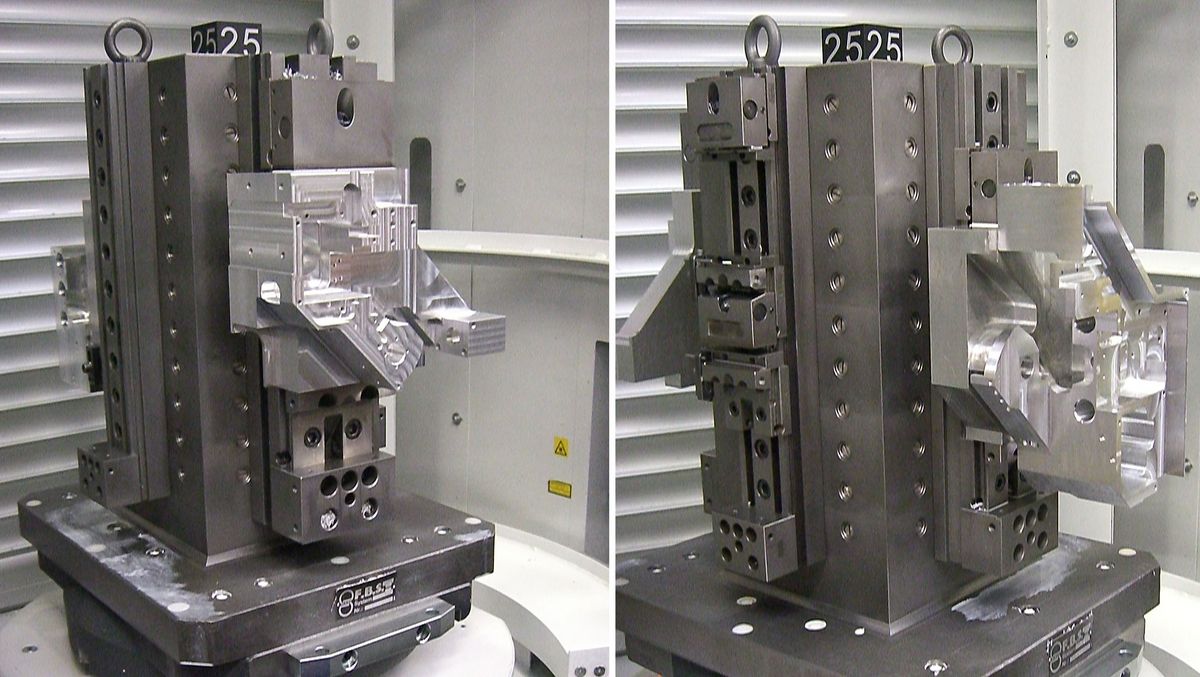

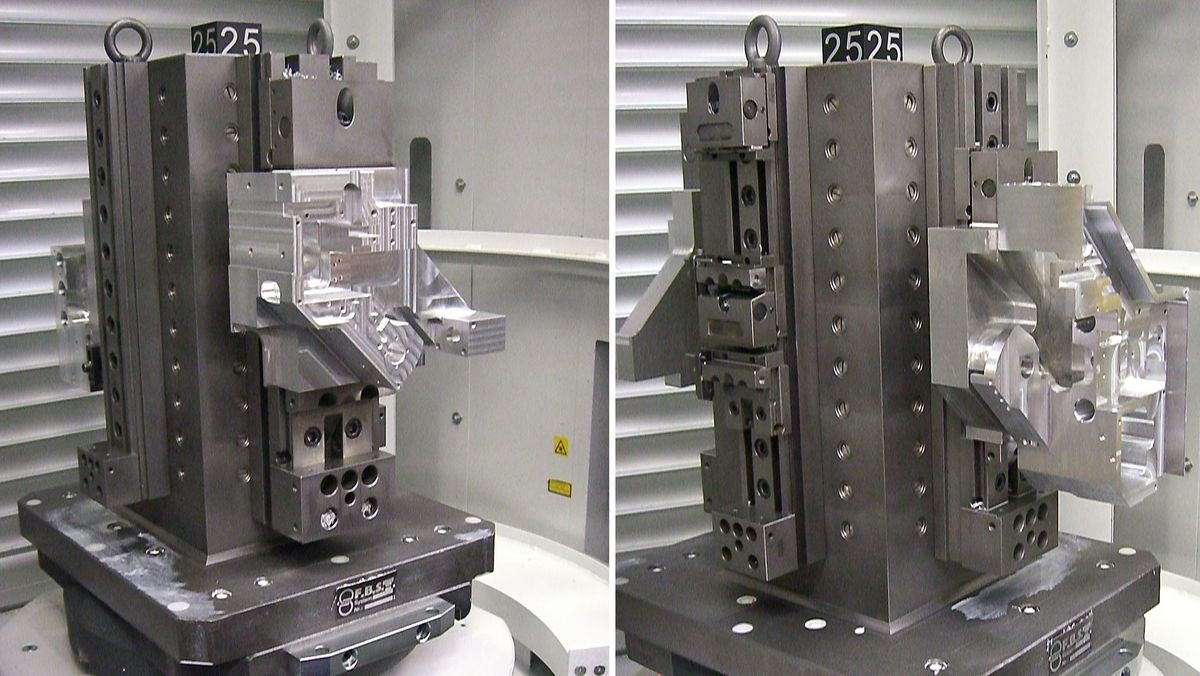

Until a few years ago, Komax handled the complete manufacturing volume with three machining centers. Since 2018, the company’s 150 different components are machined on two HELLER 4-axis machining centers model H 2000. Increased feeds, speeds and a large tool magazine have made the process 20% faster and eliminated one manned shift.

Task

- to accelerate and streamline a diverse production range comprising 150 items

- fewer manned shifts

- powerful machining centers with the same process reliability

- clear specifications for the control system (Siemens or Heidenhain)

- continued use of the existing NC programs for approx. 150 different items

- large tool magazine

Project scope & solution

- installation and commissioning of two H 2000 4-axis machining centers

- combination with flexible Fastems manufacturing system

- Siemens 840D solution line controller

Result

- one manned shift and one machine less

- two machining centers (instead of the three machines used previously)

- production accelerated by up to 20% thanks for faster control, more feed and higher speeds

- maximum of 409 tools in use

Contact

Contact

Sales & Services

Do you have questions about our products and services? Please get in touch with us, we are here for you! Benefit from our global HELLER network with knowledgeable sales and service contacts located in your region.

Find your nearest personal contact.

No results could be found.

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!