HELLER solutions at ZF

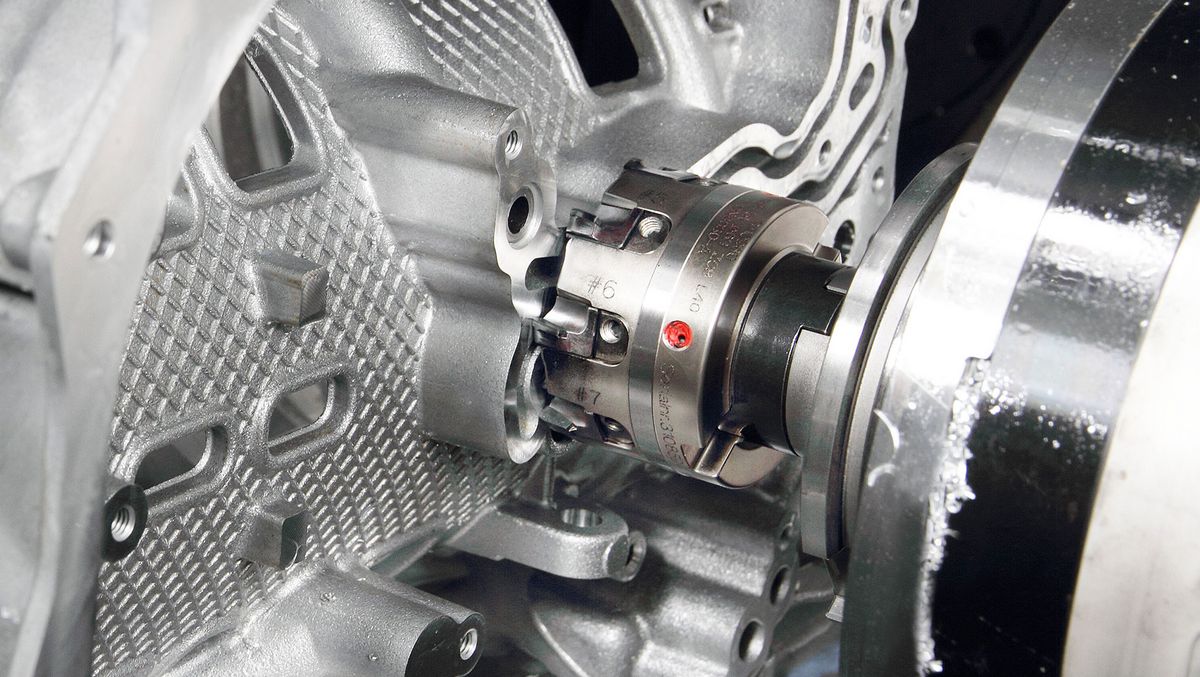

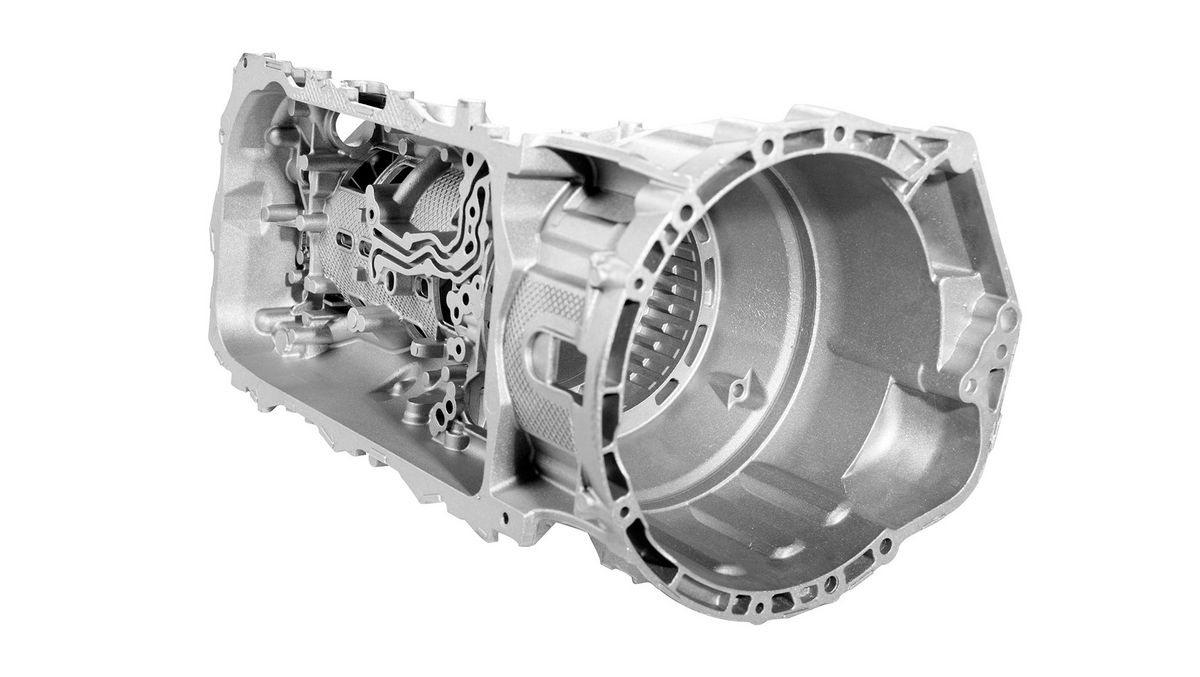

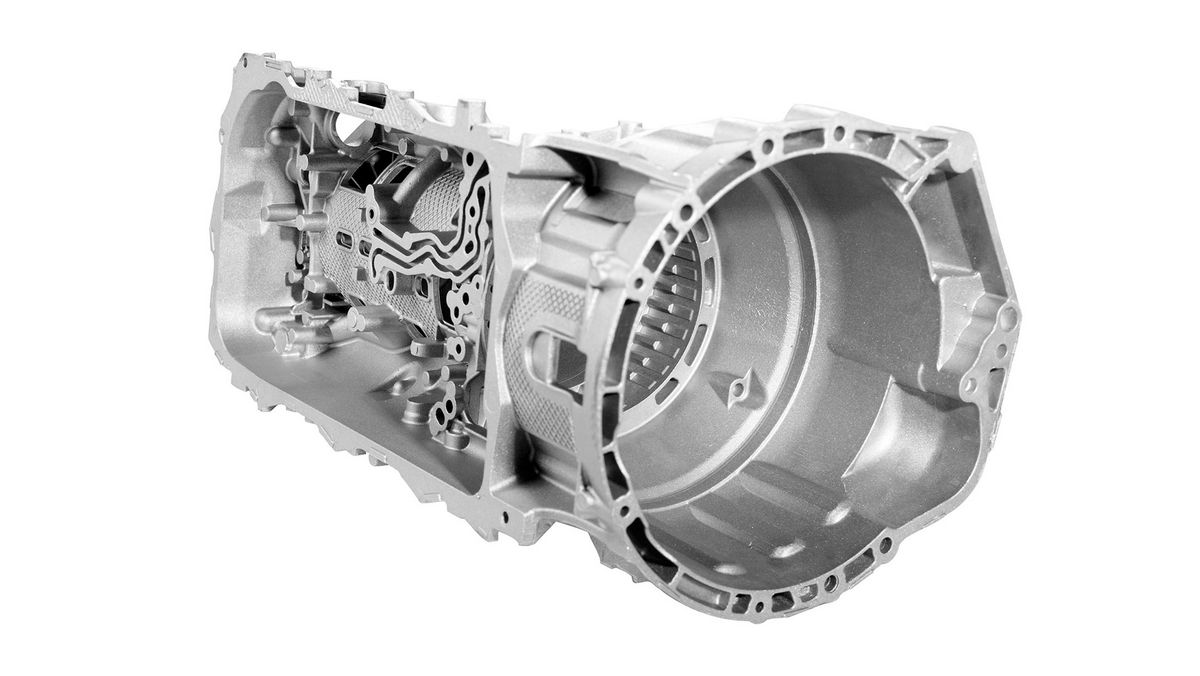

New 8-speed automatic gearbox produced on the HELLER ModuleLine

The wide variety of parts was to be machined randomly. With ModuleLine, HELLER delivered powerful machining modules for cubic components. Ever since, 750 units per day are machined with cycle times below 100 seconds. Moreover, several variants can be machined at the same time with minimal effort.

Task

- flexible manufacturing system for high part diversity

- "chaotic" production of all variants on one system for just-in-time delivery for assembly

- production with adapters for the highest possible accuracy

- loading and unloading of raw and finished parts in the same place

Project scope & solution

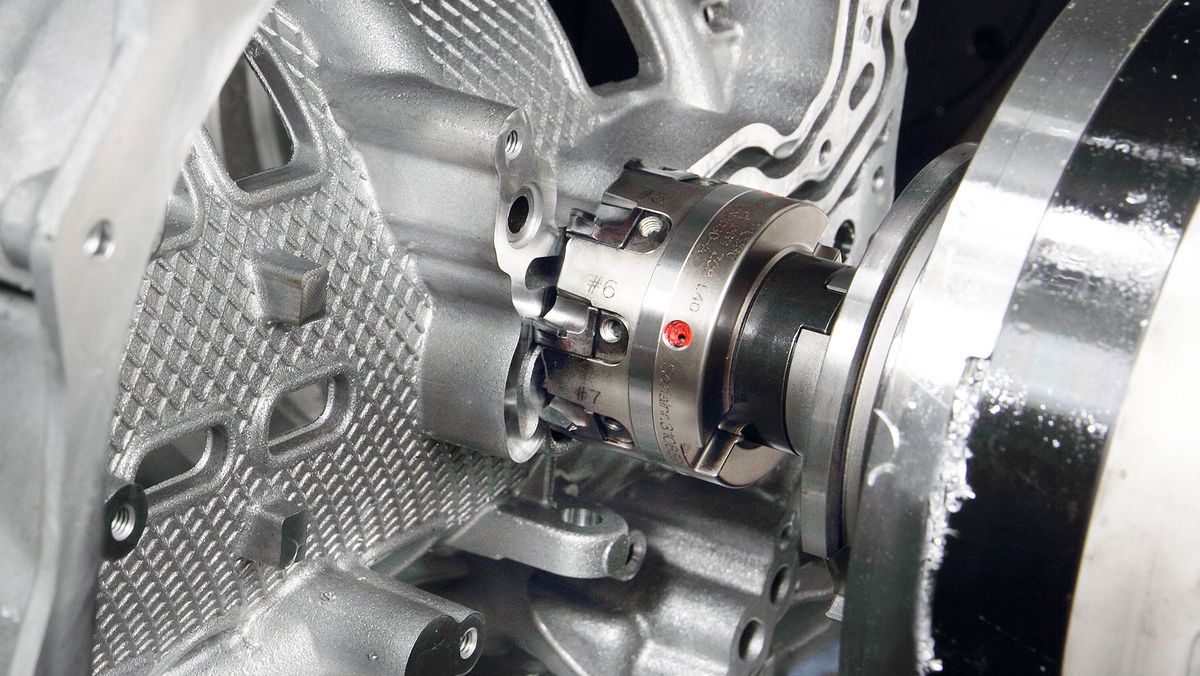

- ModuleLine from HELLER: Powerful machining modules for cubic components, series production

- flexible loading concept: manual and fully automatic

- machining modules arranged on two sides with central, floor-supported loading system

- three handling systems that move independently of one another

- development of a standardized workpiece carrier for a standard clamping concept

Result

- production time of less than 100 seconds

- 750 units per day

- simultaneous machining of several variants without equipment modifications

- due to the high demand for 8-speed gearboxes, the pilot system has been expanded by a second identical, mirror-inverted system

Contact

Contact

Sales & Services

Do you have questions about our products and services? Please get in touch with us, we are here for you! Benefit from our global HELLER network with knowledgeable sales and service contacts located in your region.

Find your nearest personal contact.

No results could be found.

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!