HELLER solutions at Meusburger

Performance milling with 25% more machine stability

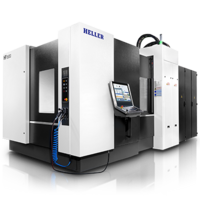

The investment in the HELLER horizontal machining center model MCH 460 was aimed at achieving an increase in productivity and availability. The high-performance milling process involves cutting volumes between 800 and 900cm3. Ever since, the stability and mechanical resilience of the HELLER machine have provided the necessary process reliability and an extended tool life.

Task

- productivity boost with better availability

- extremely high cutting parameters

- the size of the mould bases places special demands on the work area space

- the weight of the mould bases places special demands on the maximum setup mass of the pallet

- extremely high machine reliability and load-bearing capacity

Project scope & solution

- HELLER MCH 460 4-axis machining center

- optimum design of tool and workpiece clamping for chip removal rate of between 800 and 900 cm³

- Siemens 840D solution line controller

Result

- MCH 460 delivers absolute reliability

- considerable machine reserves in terms of machining force

- substantially longer tool life thanks to the machine's stability

- incredible time and cost benefits with reliable high-performance milling process

Contact

Contact

Sales & Services

Do you have questions about our products and services? Please get in touch with us, we are here for you! Benefit from our global HELLER network with knowledgeable sales and service contacts located in your region.

Find your nearest personal contact.

No results could be found.

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!